No, laying blocks in cold or wet weather is not recommended as wet or freezing conditions can affect mortar curing, compromising the strength and durability of the structure. However, with the right techniques and materials, it’s possible to work safely and achieve reliable results.

In this blog, we’ll explore the challenges of weather, solutions for working in these conditions, and practical tips for your bricklaying team to maintain quality.

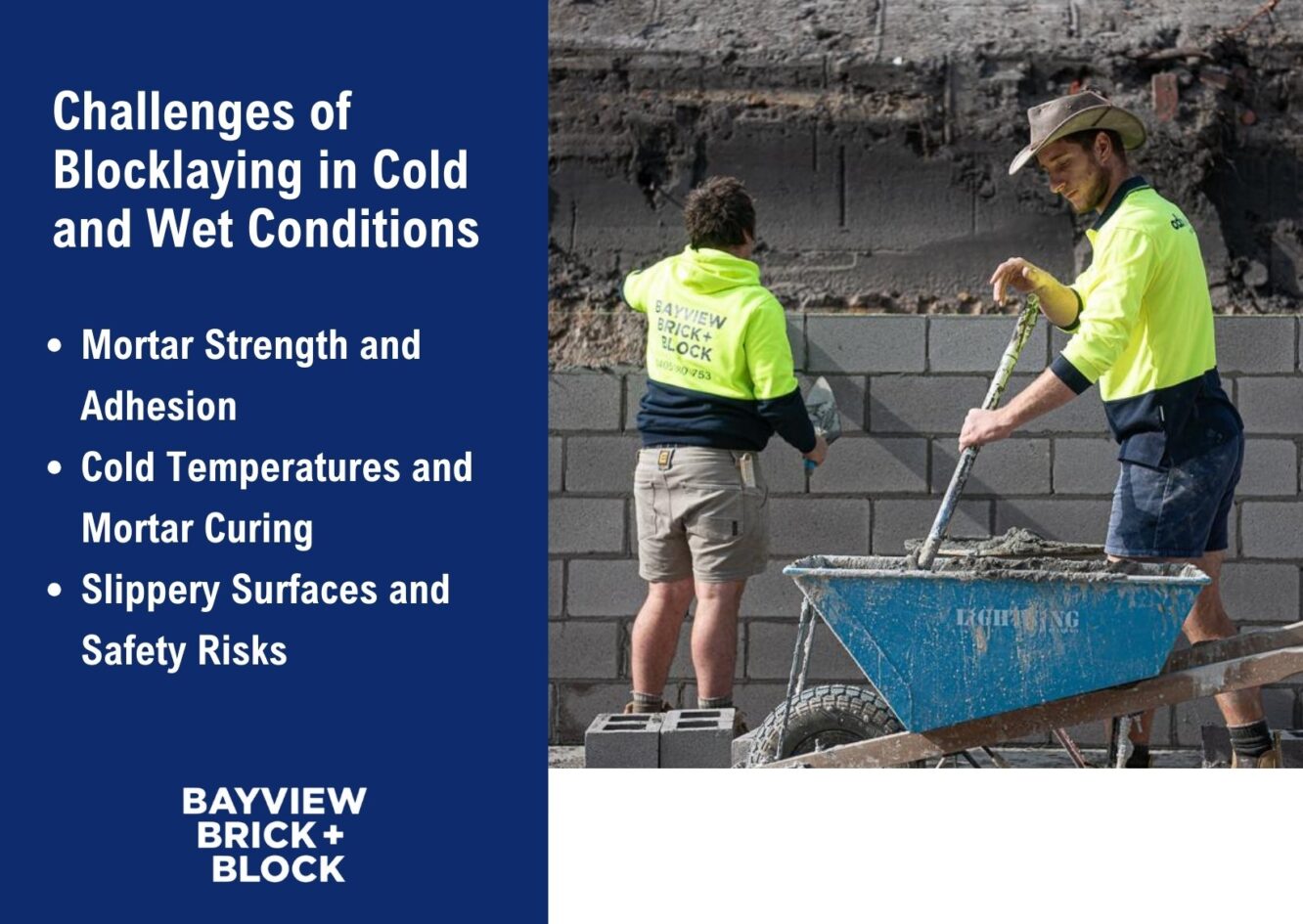

Challenges of Blocklaying in Cold and Wet Conditions

Cold and wet weather creates unique difficulties for blocklaying projects. These conditions can impact the materials, slow down progress, and jeopardise structural integrity. Understanding these challenges is vital to ensuring a high standard of workmanship. Below, we outline key issues blocklayers face when working in less-than-ideal weather.

Mortar Strength and Adhesion

Moisture in the air or rainwater can weaken mortar, affecting its ability to bond with blocks. This leads to reduced structural strength, especially when laying a private block fence or similar projects. To counteract this, careful attention to water-to-mix ratios and drying times is critical.

Cold Temperatures and Mortar Curing

Cold temperatures can halt the curing process, leaving mortar brittle and unstable. Blocks laid in freezing weather risk separation due to improper setting. Using additives or heating materials helps maintain mortar quality during cold snaps.

Slippery Surfaces and Safety Risks

Wet blocks and scaffolding create slippery surfaces, increasing the risk of accidents. Workers must navigate the site cautiously while handling materials. Ensuring proper drainage and using anti-slip measures can reduce these hazards significantly.

How Temperature Affects Mortar Strength and Curing

Wet and freezing conditions present serious challenges for blocklaying projects. Rainwater saturates materials, making blocks heavier and more difficult to manoeuvre, while also diluting mortar mixes and reducing their effectiveness.

In colder temperatures, mortar struggles to cure properly, resulting in weak joints and structural instability. Additionally, wet surfaces create slip hazards, increasing the risk of accidents and slowing progress on-site.

To address these issues, using weather-resistant additives and covering materials can provide some relief, but working under such conditions still requires extra care. Effective planning and thorough site preparation are essential to ensure delays are minimised and quality is maintained.

Protective Measures for Blockwork in Harsh Weather

Working in extreme weather demands extra precautions to protect materials and maintain quality. Taking proactive steps can minimise delays and prevent structural issues caused by wet or freezing conditions. Below are essential protective measures to consider:

- Use Covers and Tarps: Shield blocks, mortar, and other materials from rain and frost with durable coverings. This prevents saturation and ensures they remain usable.

- Add Weather-Resistant Products: Incorporate additives into mortar to improve curing and strength in cold or wet environments. These products help maintain bond integrity.

- Prepare Proper Drainage: Ensure the site has adequate drainage to prevent water pooling, which can damage materials and create hazards. This keeps the work area safer and more efficient.

- Monitor Curing Conditions: Use thermal blankets or heating equipment to support mortar curing in colder weather. These tools help maintain suitable temperatures for proper setting.

- Plan Around Weather: Schedule work during milder conditions whenever possible. Adjusting timelines can reduce the risks posed by extreme weather.