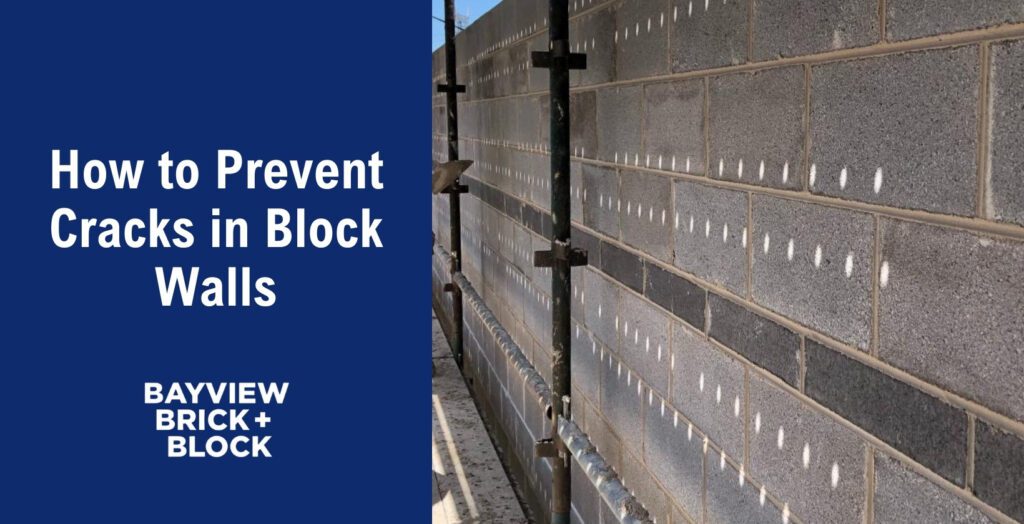

You prevent cracks in block walls by ensuring proper reinforcement, controlled curing, and strategic expansion joints. Poor construction techniques, soil movement, and moisture variations can weaken blockwork, leading to fractures. Using correct reinforcement methods from a trusted blocklaying service provider and allowing for thermal movement helps maintain long-term integrity.

Our blog will cover why cracks form, how reinforcement and joint placement improve durability, and why proper curing reduces shrinkage-related failures.

Common Causes of Cracks in Blockwork

Cracks in block construction weaken structures and lead to costly repairs. Movement in the ground, temperature shifts, and poor construction methods all contribute to damage. Identifying the cause early prevents further deterioration.

The following are the most common causes of cracks in blockwork:

Soil Movement

Ground conditions affect the stability of block walls. Expansive clay swells when wet and shrinks in dry conditions, putting pressure on masonry. Unstable fill or poorly compacted soil causes uneven settlement, leading to cracks.

Thermal Expansion

Temperature changes make blocks expand and contract. Without proper expansion joints, this movement builds stress that fractures masonry. Hot weather increases the risk, especially in long, unbroken walls.

Poor Mortar Mix

Weak mortar fails under pressure. Too much water weakens the bond, while an incorrect cement-to-sand ratio reduces strength. Blocks shift when mortar crumbles, creating gaps that allow further movement.

Inadequate Reinforcement

Steel reinforcement improves structural integrity. Without enough horizontal or vertical reinforcement, walls struggle to resist load-bearing stress. Over time, unreinforced sections crack as pressure builds.

Find out the differences in load bearing vs non-load bearing block walls here.

Best Practices for Reinforcement and Expansion Joints

Reinforcement and expansion joints strengthen blockwork and reduce cracking. Without proper support, walls struggle to handle pressure from movement, temperature changes, and external loads.

Below are the best practices for reinforcement and expansion joints:

Correct Reinforcement Placement

Steel bars and mesh provide extra strength. Horizontal and vertical reinforcement distribute stress evenly, preventing weak points. Blocks with core filling hold better against pressure, reducing the risk of cracks.

Expansion Joint Spacing

Movement gaps allow masonry to expand and contract. Placing joints at the right intervals prevents uncontrolled cracking. Long walls, corners, and openings need well-planned spacing to manage stress.

Tying Reinforcement to Blockwork

Securing steel to blocks improves load distribution. Loose reinforcement shifts under pressure, causing instability. Using ties or anchors locks everything in place, preventing separation.

Using Control Joints

Strategic cuts guide cracking along planned lines. Without them, stress builds in random spots, leading to unpredictable fractures. Placing these joints correctly helps manage movement without damaging the structure.

Proper Curing to Minimise Shrinkage Cracks

Curing plays a critical role in concrete strength and durability. Without enough moisture, fresh concrete loses water too quickly, leading to shrinkage and surface cracks. Consistent hydration allows cement particles to bond properly, reducing weak spots that compromise the slab.

Different curing methods suit different conditions. In warm weather, covering with hessian or polythene sheeting locks in moisture, preventing premature drying. Spraying water at regular intervals also helps, though it requires close monitoring. Liquid curing compounds offer another option, forming a seal that slows evaporation.

Choosing the right approach keeps the surface stable and limits defects that weaken the structure over time.