Blocklaying is faster than bricklaying due to the larger size of blocks, which covers more area with fewer units. With each block replacing multiple bricks, courses rise quickly, reducing labour hours. A skilled residential blocklayer will still play a key role, but the method demands less intricate work than traditional bricklaying.

In our blog, we’ll break down the speed differences, skill and labour needed for each approach, and how costs and efficiency impact project choices.

Speed Comparison Between Block and Brick Construction

Blocklaying moves faster than bricklaying because blocks cover more ground with each unit placed. Fewer joints mean less mortar is needed, cutting down on mixing and trowelling time. With each course rising quickly, structures take shape in fewer days compared to brickwork.

Bricklaying takes longer due to the smaller size of each unit. More individual pieces require placement, alignment, and joint finishing, adding to the time needed per square metre. Precision plays a bigger role in achieving a clean finish, slowing progress compared to blockwork.

Projects like block retaining walls benefit from the speed of block construction. Larger units allow for quicker reinforcement and backfilling, reducing delays. Efficiency on site improves when fewer materials require handling, making blocks a preferred choice for large-scale builds.

Labour and Skill Level Required for Each Method

Blocklaying demands strength and efficiency but requires less precision than bricklaying. The larger size of each unit speeds up placement, reducing the number of joints that need levelling. With fewer materials per square metre, handling and setting take less effort compared to traditional brickwork.

Bricklaying needs a steady hand and attention to fine details. Smaller units mean more courses, increasing the need for precise alignment and consistent mortar application. Achieving a clean, uniform finish takes skill, making experienced tradespeople essential for high-quality results.

Training for blocklaying focuses on handling weight and managing materials efficiently. Laying techniques, joint spacing, and reinforcement knowledge help maintain structural integrity. Experience with blockwork curing time ensures a strong, long-lasting finish, reducing the risk of cracks or weak spots.

Bricklayers spend more time mastering intricate bonds and finishing techniques. Clean jointing, correct spacing, and straight courses take practice, adding complexity to the trade. With detailed work involved, projects often require more time to achieve the desired aesthetic.

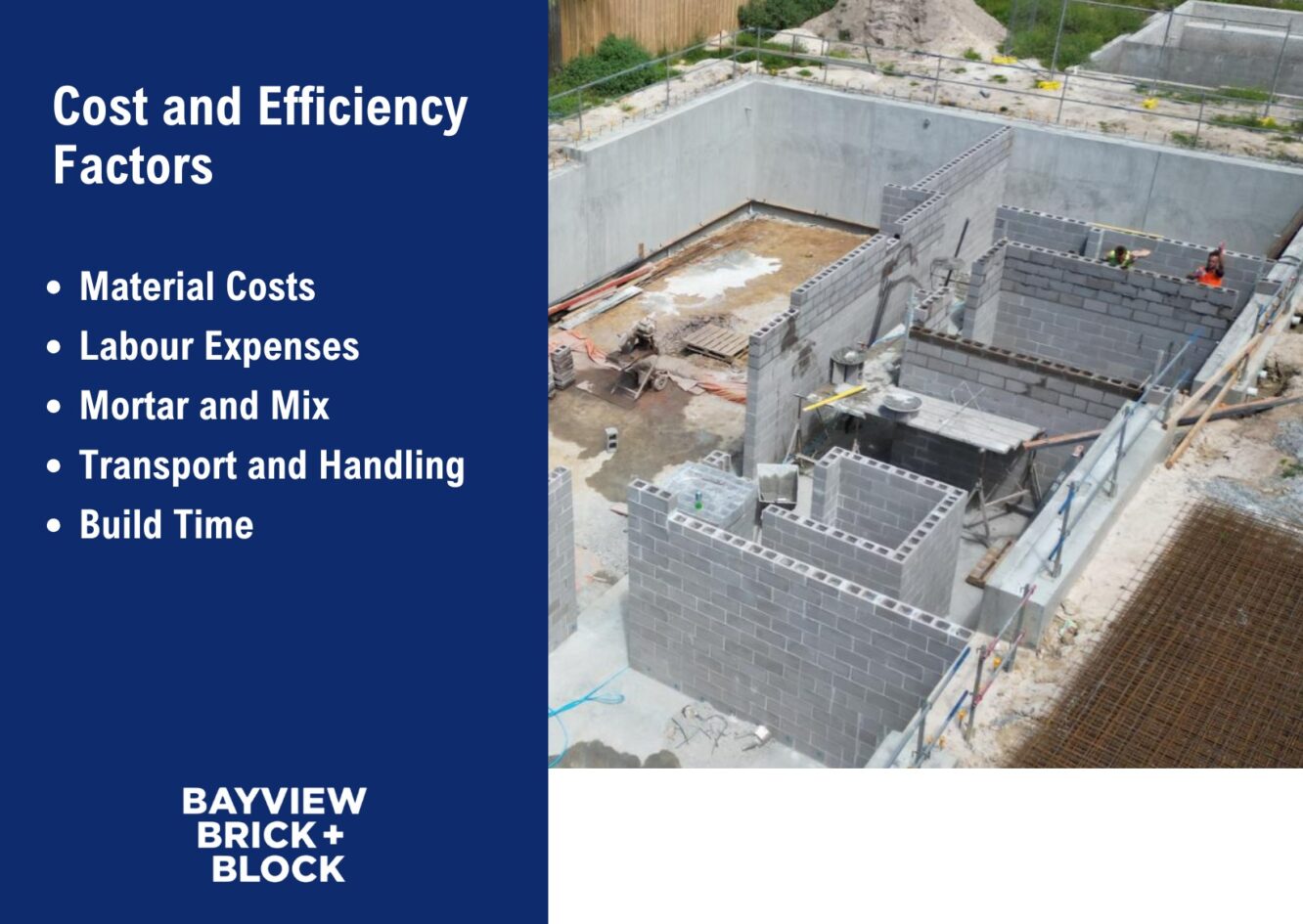

Cost and Efficiency Factors

Materials, labour, and site conditions impact overall expenses and productivity. Blocks generally offer faster build times, while bricks provide more intricate finishes.

Understanding key cost and efficiency factors helps with choosing the best method for each project.

- Material Costs: Blocks cover more area per unit, reducing the total number needed. Bricks require more individual pieces, increasing material expenses.

- Labour Expenses: Laying blocks takes fewer hours, cutting down on wages. Brickwork involves more detailed placement, leading to higher labour costs.

- Mortar and Mix: Blocks use less mortar due to fewer joints, lowering supply needs. Bricks demand more mix, adding to overall material use.

- Transport and Handling: Blocks weigh more per unit but need fewer deliveries. Bricks take up more space and require extra handling.

- Build Time: Blockwork progresses faster, allowing for earlier project completion. Bricklaying moves slower, especially for decorative finishes.