You build a block fence for privacy and security by carefully selecting durable materials and following proper construction techniques. This type of fence not only enhances your property’s safety but also adds long-lasting value. A reliable approach involves expert craftsmanship, especially when engaging an experienced blocklaying company to ensure professional results.

This guide covers everything from choosing the right blocks to step-by-step building instructions, along with reinforcement methods for wind and structural stability.

Choosing the Right Blocks for a Durable Fence

Choosing the right blocks is essential for building a durable fence that withstands the elements. Dense concrete blocks are ideal due to their strength and resistance to cracking over time. Smooth or textured finishes can be selected to complement your property’s style while providing a sturdy barrier.

Consider the local climate when selecting materials, as certain blocks handle different conditions better. For instance, moisture-resistant options are critical for preventing damage to blocks in rainy weather. Proper drainage around the foundation further helps maintain the integrity of the fence in challenging conditions.

Matching the block size to your fence design ensures stability and ease of construction. Thicker blocks are better suited for higher structures, providing the necessary support. Always prioritise quality materials to create a fence that remains solid for years to come.

Step-by-Step Guide to Building a Block Fence

Building a block fence requires planning, precision, and the right techniques to achieve a strong and lasting structure. By following these steps, you can ensure your fence provides the privacy and security you need.

Below is a step-by-step guide to help you get started.

Step 1: Plan and Measure

Begin by marking the fence line and measuring the dimensions of the area. Use these measurements to calculate the number of blocks and materials required. Clear the space of debris to prepare for construction.

Step 2: Lay the Foundation

Excavate a trench along the marked line to create a stable footing. Pour reinforced concrete into the trench and allow it to cure completely. This base ensures the fence remains steady over time.

Step 3: Lay the Blocks

Start placing blocks from one corner, applying mortar evenly between each layer. Use a spirit level to check alignment and make adjustments as needed. Work systematically to maintain consistency and strength.

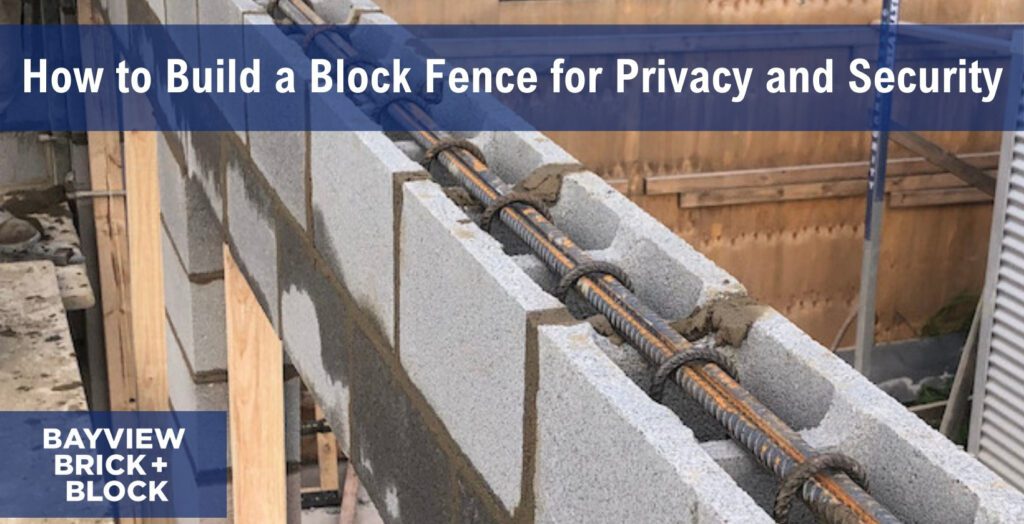

Step 4: Reinforce the Structure

Insert steel reinforcement rods into the blocks at regular intervals for added stability. Fill the cores with concrete to strengthen the fence, especially for taller designs. Reinforcement is key for fences that need to build soundproof block walls.

Step 5: Finish and Seal

Smooth out the mortar joints and remove excess material for a neat appearance. Apply a weather-resistant sealant to protect the fence from moisture and wear. Let the structure cure properly before using or decorating it.

Reinforcement Techniques for Wind and Structural Stability

Reinforcing a block fence is crucial for maintaining stability and ensuring it can withstand strong winds and external pressures. Proper techniques strengthen the structure and prevent damage over time.

Let’s take a look at the key methods to reinforce block fences effectively.

- Steel Reinforcement: Insert steel rods vertically through the hollow cores of blocks. These bars provide added strength, especially for taller or exposed fences.

- Core Filling: Fill the hollow sections of the blocks with concrete after installing reinforcements. This creates a solid structure capable of resisting pressure and movement.

- Anchoring: Secure the base of the fence into a reinforced concrete footing. This prevents shifting and enhances overall durability in adverse conditions.

- Bracing: Add cross-braces or pilasters at regular intervals for additional lateral support. These features distribute force evenly, reducing the risk of structural failure.

- Expansion Joints: Include expansion gaps to allow for natural movement from temperature changes. These joints minimise the likelihood of cracks forming in the structure.